The integrated sieving systems go beyond the traditional concept of a standalone vibrating sieve, combining advanced screening technology, integrated process control, and enhanced safety into a single, modular and customizable solution.

Developed to provide a complete and reliable approach to screening, an integrated system increases sieving productivity while protecting the equipment in the event of machine downtime. Each system is unique, fully integrable, and customizable according to the customer’s specific requirements. Every project is designed with a strong focus on inert environment safety and full process control.

The main features of the system include continuous monitoring of safety levels in inert environments to ensure maximum operational protection, as well as correct and controlled feeding of the sieve.

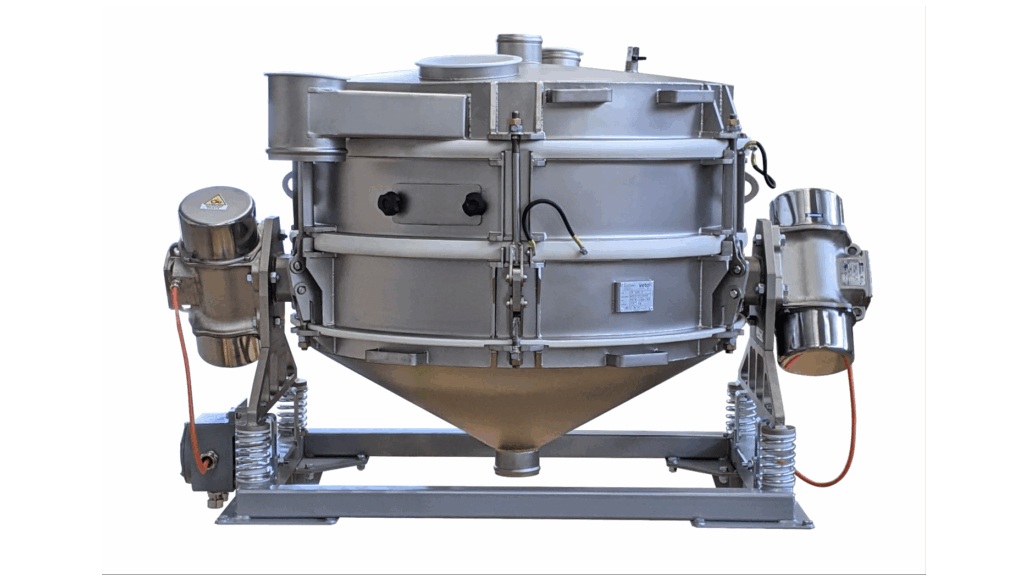

The technology employed is multifrequency. Standard vibration is transformed into multiple vibration frequencies, which are transmitted directly to the screening mesh, providing the following advantages:

– significant reduction in mesh blinding

– capability to screen metal powders down to 7 microns

– effective de-agglomeration of lumps, ideal for highly cohesive food materials such as powders with high fat or sugar content

– minimized dispersion of fine powders, as each particle encounters the most suitable screening frequency to pass through the mesh.

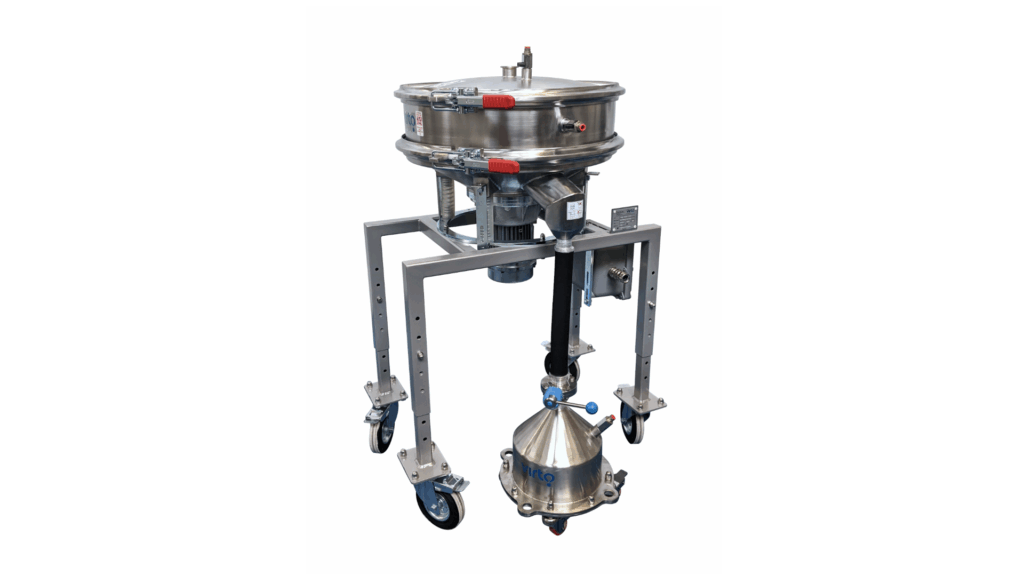

The system consists of product feed bins connected to a customizable docking station. Feeding is managed to ensure a controlled and constant flow toward the vibrating sieve, the core of the screening system. The classified material is collected in dedicated discharge bins.

Control of the entire plant is handled by an integrated PLC panel, supported by one or more oxygen analyzers that ensure process safety and the maintenance of the inert zone. The system is operated through a dedicated interface that allows the operator to monitor and manage all functions in a simple, intuitive, and safe manner.