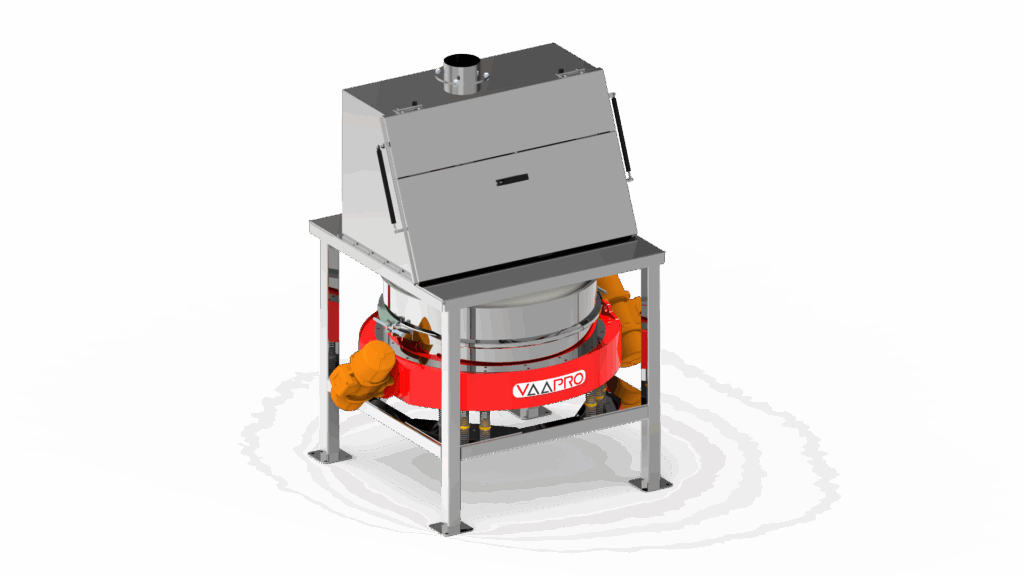

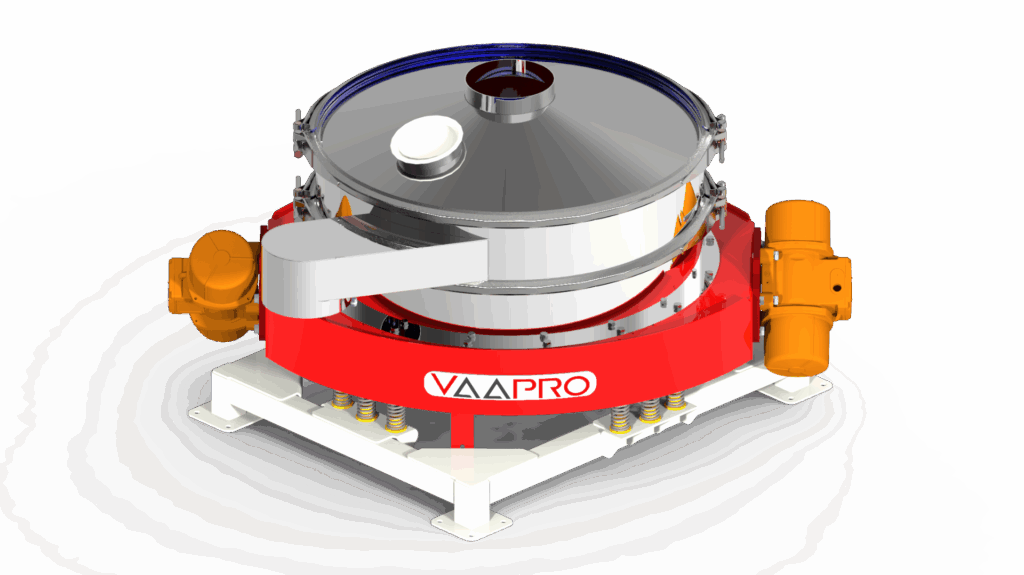

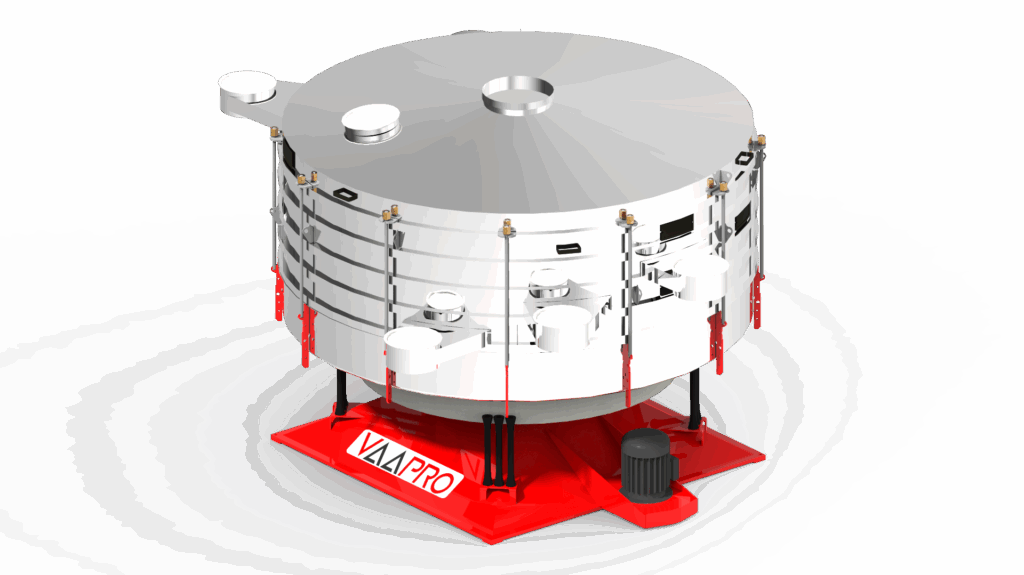

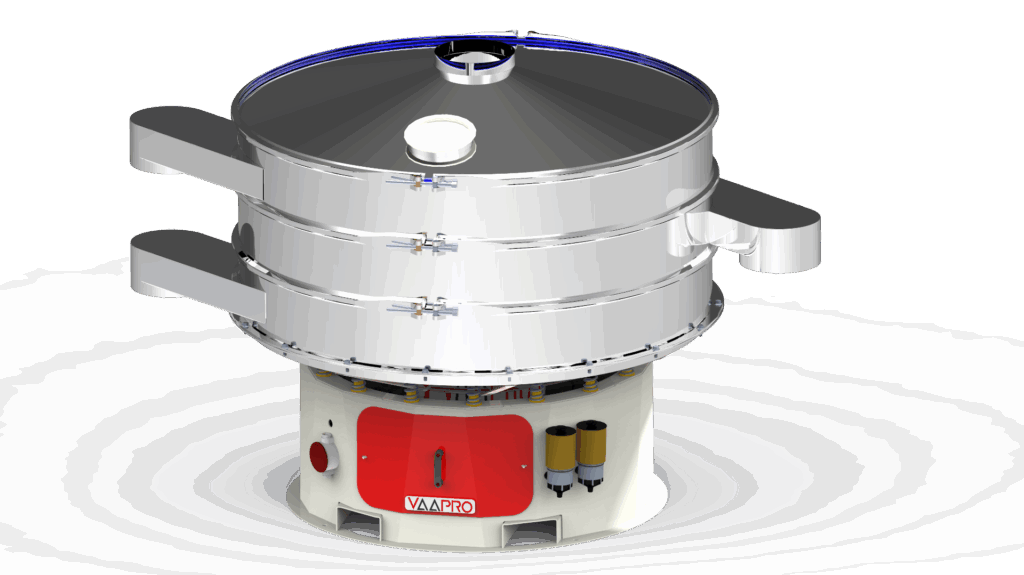

Vaapro Rectangular Sieves – High-Capacity Screening for Demanding Applications

At Solids Parma 2026, Vaapro introduces its advanced line of Rectangular Sieves, engineered to deliver high throughput, precision screening, and robust performance for bulk solids processing.

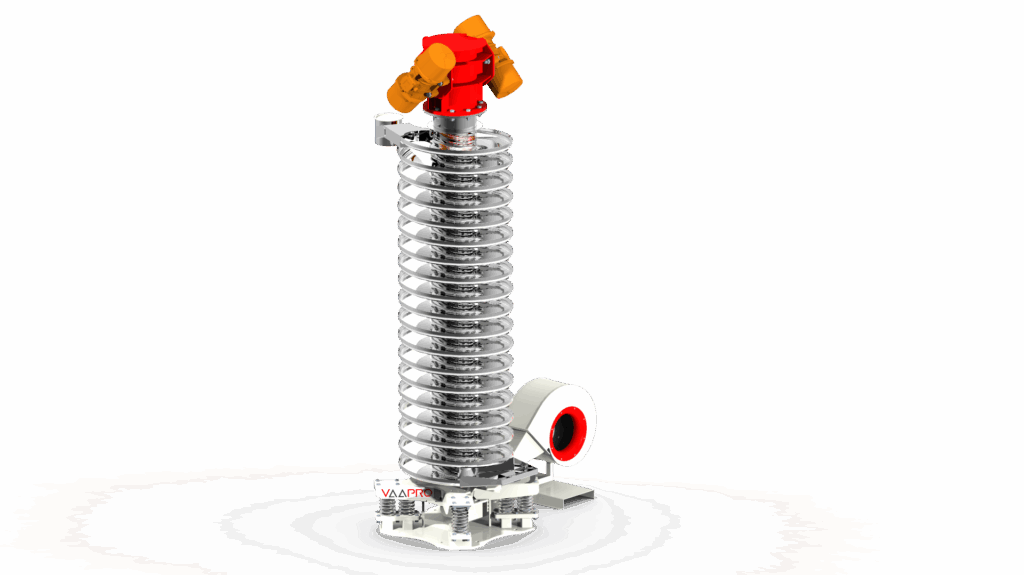

Designed for industries such as chemicals, food, pharmaceuticals, minerals, and recycling, Vaapro rectangular sieves are ideal for scalping, grading, and de-dusting of powders and granules, even under continuous operation and heavy-duty conditions.

Key features of Vaapro Rectangular Sieves include:

– Large screening surface for high-capacity processing;

– Efficient material flow, even with difficult or abrasive products;

– Robust, vibration-resistant structure for long-term industrial use;

– Multiple deck configurations available for multi-fraction separation;

– Easy access and quick-clean design, minimizing downtime and ensuring compliance with hygiene standards;

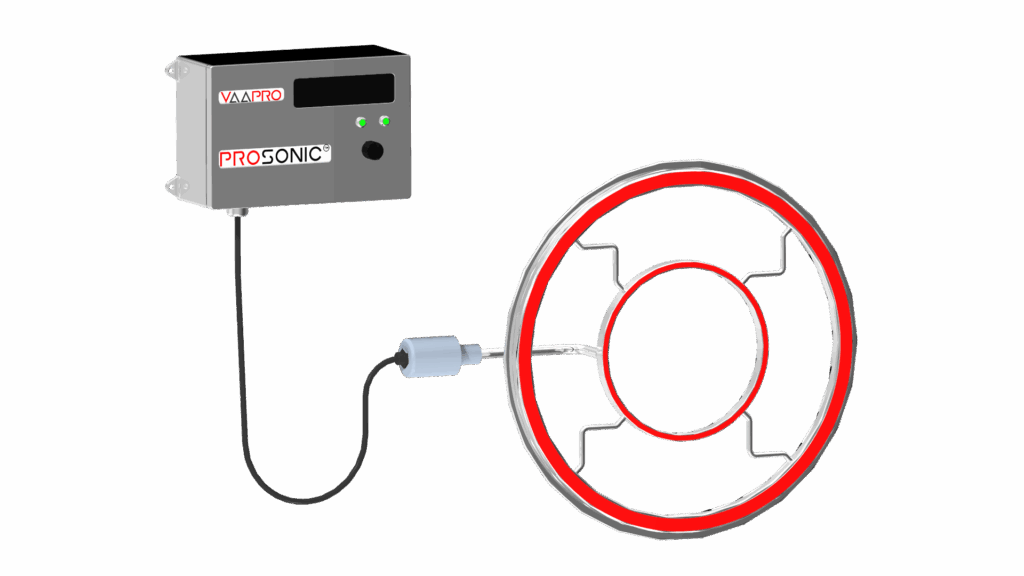

Built with stainless steel frames, FDA-compliant gaskets, and customizable mesh sizes, the rectangular sieves can be tailored to suit a wide variety of applications. Options include dust-tight covers, ultrasonic systems integration, and ATEX compliance for use in hazardous environments.

Whether integrated into a new line or retrofitted into existing setups, Vaapro rectangular sieves help optimize screening efficiency, reduce waste, and improve overall product quality.