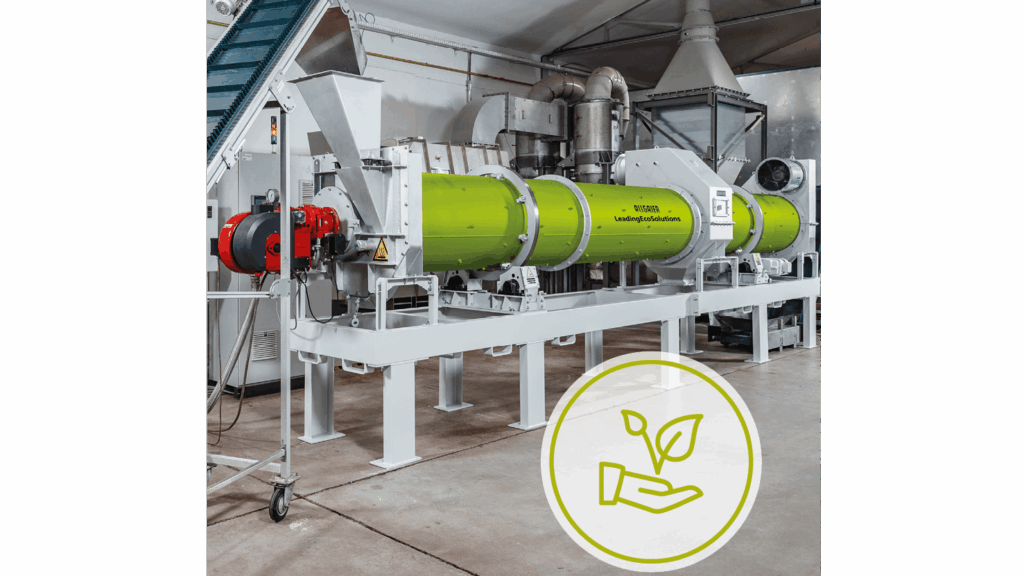

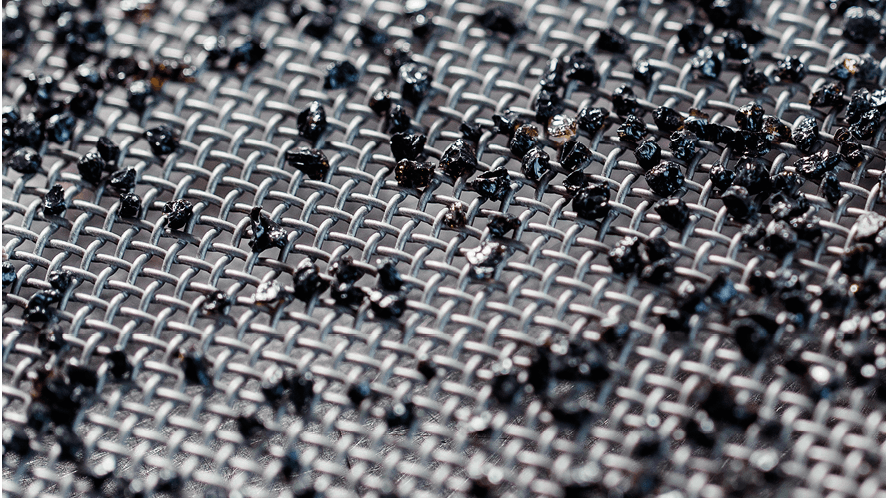

Combined Drum Dryers/Coolers from Allgaier are available in single-shell, double-shell and triple-shell designs. All three designs are combined systems in which drying and cooling take place in a single unit. Therefore, only one drive and one bearing are required in each case. Combined Drum Dryers/Coolers are offered in three types: TK, TK+ and TK-D. While the TK type is cooled by means of ambient air cooling, the TK+ uses evaporative cooling. The TK-D type is a further development. The TK-D complements the previous systems by offering the possibility of cooling to particularly low solid temperatures as well as efficient heat recovery and the resulting energy savings. The systems are particularly suitable for the processing of thermally and mechanically relatively insensitive, free-flowing bulk materials such as gravel, quartz and natural sands as well as limestone crushed sand.

Benefits:

– High performance: Very insensitive to fluctuations in material moisture, material grain size and feed rate.

– High efficiency: Highest thermal efficiency due to very high hot gas temperatures and very high internal temperature difference.

– Robust design: Very robust design for maximum service life with minimum maintenance costs.

– Maximum flexibility: Easy to combine with a wide variety of heating systems and different fuels.

Type TK-D:

– High performance: Cooling of the dried solids to particularly low temperatures to close the ambient temperature/temperature of the cooling air used.

– High efficiency High energy efficiency through heat recovery in the drying process and evaporative cooling in the cooling process.

– Multiple usage areas: Can be used for countercurrent calcination with subsequent cooling.