SEW North Filtration and DKIT Filters offer a wide range of high-efficiency air filtration products. With over 60 years of experience in the filtration industry, we can offer the best products on the market.

We offer a comprehensive range of filter elements covering all market standards, but we are also able to create new ones based on customer need. Our filter elements are not only functional and well-constructed, but also aesthetically pleasing and for our customers’ safe, all materials used in the production are traceable.

All our filter fabrics are BIA Class “M” rated and certified by an independent laboratory, in accordance with the DIN 60335-2-69:2015 standard. This standard requires quartz powder (with approximately 90% of particles between 0.2 and 2.0 microns) to be filtered through the fabric within pre-established parameters. The degree of penetration achieved determines the filter media’s efficiency class. For class “M,” the maximum permitted dust passage is less than 0.1%.

Our 19,000 m2 production site (8,000 m2 of which is covered) is located in the Maribo Business Park, 15 minutes from the ferry terminal for Germany and the Fehmarn Belt tunnel on the E47.

With a team of 50 people, we produce approximately 140,000 filter elements/year, with a full-time capacity of 420,000 pcs/year.

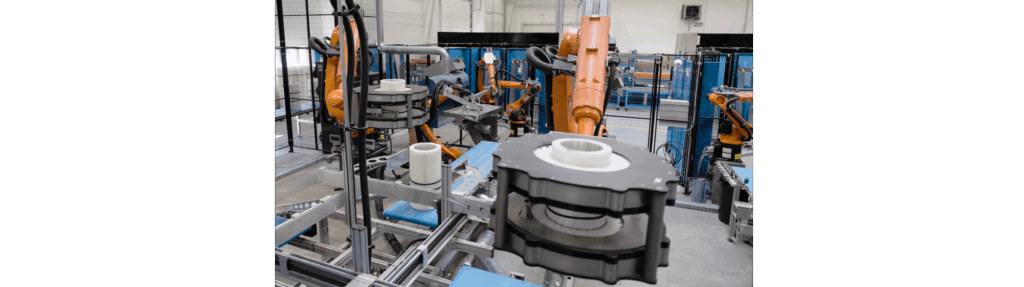

Each robot line is composed by three smaller robots that supply materials, in addition to a larger one that moves the filter cartridge through the various production stages.

Our 1,040 m2 warehouse, combined with our 1,000 m2 material procurement and storage system, allows us to have any type of fabric or part available for producing your filter elements at once.

We design custom filtration systems to ensure clean air in every work environment. Thanks to innovative solutions and high-quality materials, we create efficient, reliable, and customized systems, tailored to each client’s specific needs.

Our skilled technicians have decades of experience on the ground and are constantly updated on the latest developments.

We offer scheduled and preventative maintenance contracts, helping to reduce production downtime and operating costs over time.