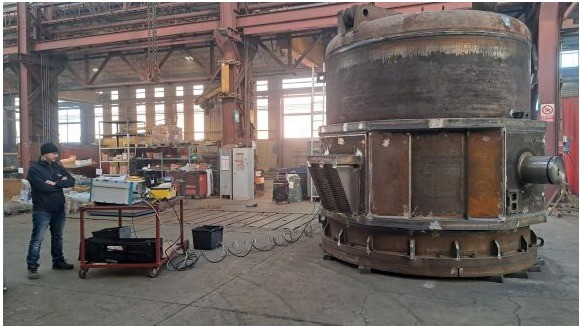

Residual stress relief service using low-frequency mechanical vibrations: the evergy-saving alternative to furnace annealing heat treatment.

In the previous edition of SOLIDS 2024, many of you asked us about our vibratory stress relief service, dedicated to reducing residual stresses in metalwork and forging components.

This technology, widely used in the US since the 1960s, is still little known in Italy.

Barra Project International boasts over 50 years of experience using this technology and a truly impressive history of vibratory stress-relieved components.

What are the advantages of using vibratory stress relief?

The component is treated directly in the plant where it was produced.

The component treated with vibratory stress relief is easier to work with.

Greater dimensional stability of the component during subsequent use.

Reduced risk of component fatigue failure.

The treatment lasts approximately 2 hours.