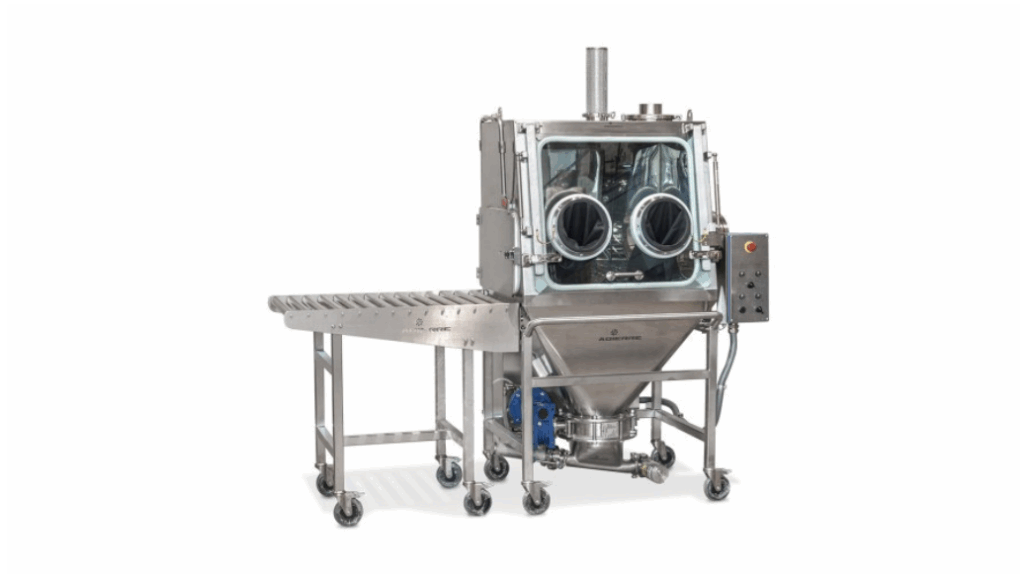

HopperPress is a dense-phase pressure conveying system designed to transfer large quantities of powders and granules over long horizontal and vertical distances, where conventional vacuum conveyors are not suitable.

Using pressurized air as the driving force, HopperPress ensures gentle material handling, preventing particle degradation, demixing, density variations, and pipeline abrasion. The system operates quietly, requires minimal maintenance, and is easy to dismantle and clean.

Manufactured with mirror-polished AISI 316L stainless steel for all product-contact parts and AISI 304 stainless steel for non-contact components, HopperPress is suitable for applications in the food, pharmaceutical, chemical, mineral, and plastics industries, where product integrity is critical.

The system transfers material by creating a controlled pressure differential between the conveying vessel and the pipeline, efficiently delivering product to the receiving unit. HopperPress complies with cGMP, FDA, UNI EN ISO, ATEX, and Machinery Directives and can be customized in terms of materials, connections, and control logic (pneumatic, electro-pneumatic, or PLC-based) to meet specific process requirements.