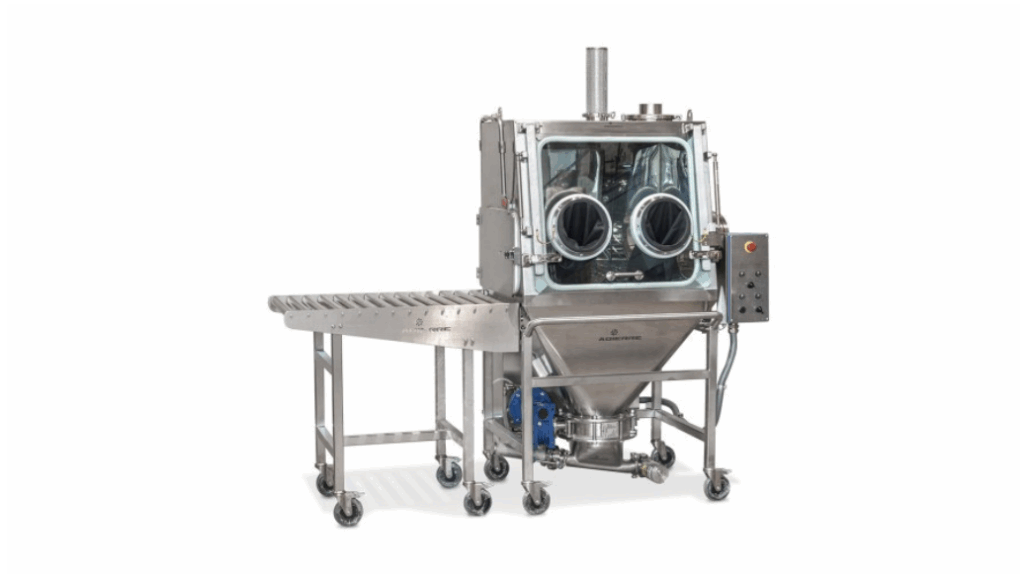

The AGR BAGPRESS Big Bag Conditioner is designed to loosen and recondition compacted bulk materials inside Big Bags, restoring a free-flowing, granular consistency. It is suitable for use in chemical and pharmaceutical environments, where reliable powder discharge is critical.

The system applies controlled electro-hydraulic compression through a massaging arm with crushing plates, combined with a rotating base that allows 360° treatment of the Big Bag. This dual vertical and horizontal action ensures effective conditioning along the entire bag height and surface, even with hard or compacted products.

Managed by a PLC-controlled automation system with touch panel, the BAGPRESS can operate in manual or fully automatic modes with programmable recipes. It is designed for easy Big Bag loading by forklift or pallet truck and can be installed even in limited spaces.

The AGR BAGPRESS complies with cGMP, UNI EN ISO, ATEX (when required), and FDA 21 CFR Part 11 regulations, falls within the Industry 4.0 category, and can be customized to meet specific process requirements while ensuring maximum operator safety.