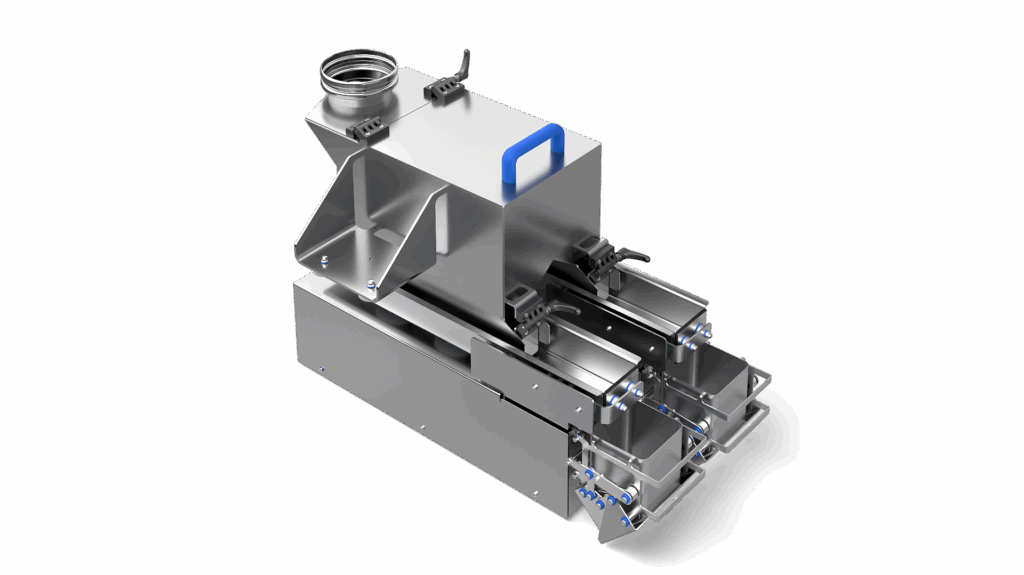

AViTEQ linear scales are used for volumetric or gravimetric dosing of bulk materials. Our systems precisely record the weight per lane and control the material feed via one or more weighing units for exact and consistent product dosing.

Precise dosing: The linear weigher is a modular dosing and weighing system for free-flowing products such as nuts, granulates, frozen vegetables or confectionery. The material is dosed into weighing hoppers in a controlled manner via vibrating chutes.

High accuracy: Thanks to the combination of coarse dosing and fine dosing, the linear scale achieves very high measuring accuracy – even at high throughput rates.

Wide range of applications: Food industry, chemicals, pet food and non-food products.

Fastest disassembly: Thanks to a well thought-out concept, the main components of the weighing hopper, conveyor trough and hopper can be removed as quickly as possible for cleaning.

Dosing and weighing in one system – linear scales

The linear scale for the food industry is a precise dosing and weighing system for free-flowing products. It is used in the food, chemical and pet food industries as well as for non-food applications. As a dosing weigher for powder and granulates, it combines the functions of dosing and weighing in one compact device. In addition to precise weighing, the linear weigher also enables the continuous feeding of packaging and processing lines. The wide range of applications of the AViTEQ linear scale at a glance:

Precise dosing and weighing

Linear weighfeeder for filling in packaging and filling systems

Portioning of small and medium-sized batches (from 10 g) with high accuracy

Consistent product feed for mixing and filling processes

Flexible adaptation to different product types and hygiene requirements

Magnetically held main components for quick removal and cleaning

Modular design – can be flexibly combined