Design engineering

– Product analysis: particle size distribution, bulk density, angle of repose, abrasiveness, moisture content, temperature, presence of lumps or fibers. These parameters determine the type of flighting, pitch, speed and material choice.

– Capacity calculation: Q = A × v × ρ (select whether expressed in volume or mass) with checks for pressure loss and required torque.

– Flighting selection: full flighting, edge flighting, ribbon flighting, multi-blade flighting depending on required capacity and material characteristics.

– Sizing: tubular or trough diameter, flight pitch, plate thickness, shaft deflection checks when a shaft is present.

– Simulations: 3D CAD, interference checks, FEM analysis for critical stresses and weight/resistance optimization.

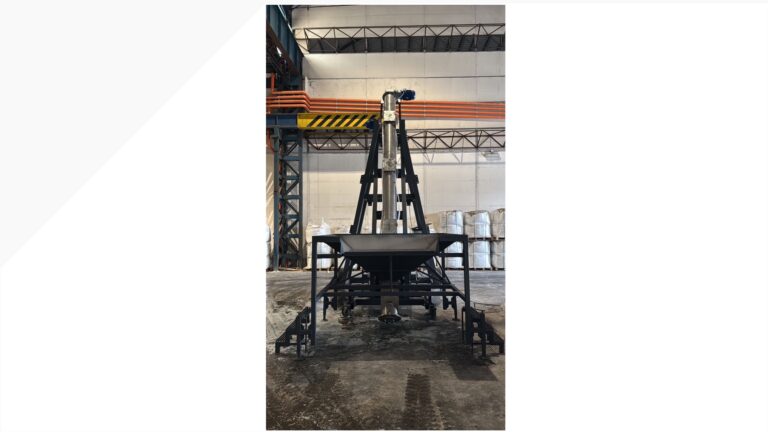

Construction types and materials

– Trough augers: open or covered troughs, easy access for cleaning; suitable for high capacities and abrasive materials.

– Tubular augers: dust containment, ability to pressurize, hygienic compliance (HACCP); suitable for corrosive environments when made in AISI 304/316.

– With shaft: greater stiffness for long lengths and concentrated loads; shaftless: reduced internal obstruction, easier disassembly, fewer wear points.

– Materials: carbon steels with coatings, stainless steels AISI 304/316, special alloys, wear-resistant linings (Hardox, ceramic, nickel-chrome), food-grade finishes (polished surfaces, sealed welds).

– Seals and gaskets: for airtight tubular versions, food-grade seals and sealed discharge systems.

Accessories and integration

– Drives: electric motors with gearboxes sized for calculated torque; IEC or NEMA motors, variable speed drives (inverters).

– Power transmission: chains, belts, elastic couplings, planetary or worm gear reducers.

– Sensors and automation: level sensors, flow counters, overload switches, PLC/SCADA integration.

– Dosing systems: ribbon valves, dosing conveyors, piston pumps for viscous liquids.

– Cleaning and safety: air cleaners, reversal systems, inspection doors, safety guards.

Maintenance and reliability

– Maintenance plans: preventive maintenance with periodic checks on flighting wear, bearings, shaft alignment and lubrication.

– Spare parts: standard and custom flighting, bearings, couplings, seals, discharge plugs.

– Downtime reduction: modular design for quick disassembly, rapid-replacement kits, operator training.

– Condition-based monitoring: vibration/temperature sensors on bearings for predictive maintenance.

Certifications and compliance

– HACCP compliance available, material certificates and plate traceability.

– Documentation: material certificates (EN 10204), execution drawings, user and maintenance manuals, declarations of conformity (CE) where required.

– Tests: in-factory trials with customer material, flow measurement, leak and noise checks.

Concrete application examples

– Food: tubular auger in AISI 316L stainless steel with polished surface, sanitary couplings, easy disassembly for CIP cleaning.

– Mining: trough auger with reinforced flighting and Hardox lining, protected bearings and inspection access.

– Chemical: auger with anti-corrosion coating and special seals for toxic powders, integrated extraction and filtration systems.

– Recycling: augers with variable pitch for bulky materials and integrated separators.

Order process and lead times

– Phase 1: data request (product datasheet), site survey and inspection.

– Phase 2: technical-commercial offer and preliminary drawings (1–2 weeks).

– Phase 3: detailed engineering and customer approval (1–3 weeks).

– Phase 4: production and surface treatments (4–8 weeks depending on complexity).

– Phase 5: testing, shipment and on-site installation; start-up and training.

Sales models

– Turnkey supply (design, components, installation).

– Modular supply (equipment only or spare parts).

– Service contracts and scheduled maintenance.

– Custom offers including extended warranty options and after-sales services.

Indicative cost estimate

– Small standard augers (light duty): quotes start from affordable levels; price varies with materials and accessories.

– Custom industrial augers: price depends on diameter, length, material, accessories and surface treatments. Detailed quotation after analysis.

Would you like me to prepare:

– A tailored quote (send product specifics: density, particle size, desired capacity, length/height, operating environment)?

– A preliminary 2D/3D drawing or a technical slide for your website/catalog?

Tell me which service you prefer and I will prepare the materials.