ATS GROUP: COMPANY, MISSION, VALUES

ABOUT US

ATS GROUP is an Italian company constantly engaged in the research, analysis and supply of new technologies and services in the field of handling, regulation and storage of fluids, gases and dusts. ATS GROUP is today a solid point of reference in the Italian industrial sector. Year after year it has consolidated its presence in thousands of companies both nationally and internationally and, thanks to investments and acquisitions, today it has several production units that allow it to operate as a Global Service specialized in the industrial maintenance sector.

OUR GOAL

We are committed to the continuous improvement of our internal processes to provide a superior level of service that can meet, and exceed, the expectations of our customers, thus becoming their trusted partner.

Since its inception, our Company has adopted procedures and systems in line with the procedures provided for by the Company Quality System.

We are certified according to the UNI-DIN ISO 9OO1-2O15 standards since 2OO2 and we follow certified organizational methods such as the 231 organizational model and the European Regulation for the protection of personal data 679/2O16 (Privacy), all described and drafted in our code of ethics.

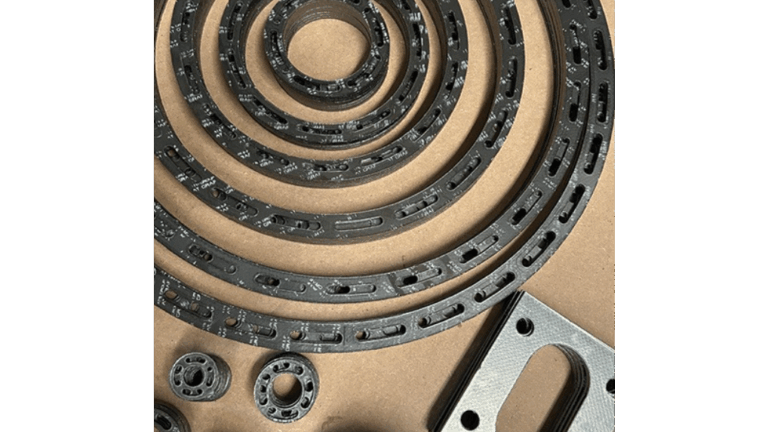

Automatic cutting and machining departments

It deals with the production of sheared and machined gaskets in standard and customized formats. It has 2 automatic machining centers and various machines for the processing of plastic material as well as a large warehouse of ready-to-use semi-finished products. In this department, natural fiber materials, rubbers, plastic, semi-metallic and metallic materials are processed.

Textile workshop

The laboratory is divided into 2 main units. One is used for the study and manufacture of textile products for the filtration of powders and liquids for the industrial and food Pharma sectors. The second deals with the production of protection systems (flange covers and safety covers) and thermal, thermal heating and acoustic insulation covers (insulating covers for valves, pumps and industrial machinery). the production of protection systems (flange covers and safety covers) and thermal, thermal heating and acoustic insulation covers (insulating covers for valves, pumps and industrial machinery).

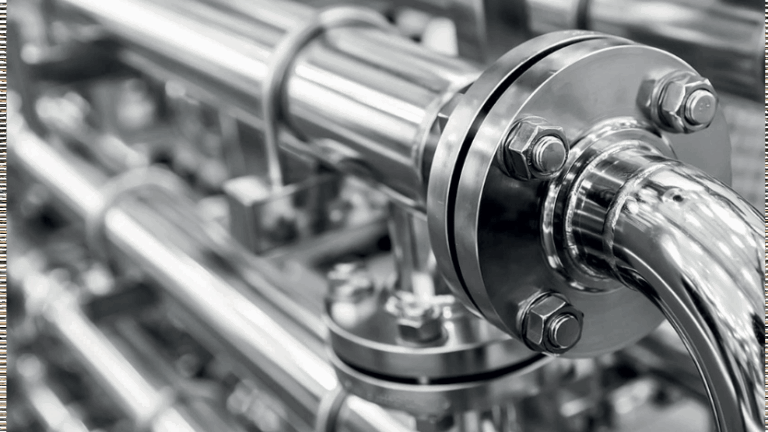

Flexible hose cutting and crimping department

In this department, flexible hoses are manufactured and tested to measure with customer-specific fittings. The main lines include composite hoses, rubber hoses, PTFE hoses and flexible steel braided hoses, all available with ATEX certification. In addition to the production of the new pipe, the test service with report and certificate is carried out in this department as a third party for our main customers. Département de coupe et de sertissage de tuyaux flexibles.

The MAINTENANCE AND SERVICE division

It is the operational arm of the group. With its own specialized staff and a fully equipped workshop, it deals with ordinary and extraordinary maintenance interventions at our headquarters or directly from our end customers. We specialize in the maintenance of centrifugal and positive displacement pumps, blowers and compressors, agitators, variators, industrial gearboxes and heat exchangers. At the Magenta headquarters, equipped with its own workshop complete with sandblasting, washing and painting department as well as a lapping and reconditioning department for mechanical seals of all brands and models, skids, small systems and customized systems are manufactured and assembled.

Our business unit

2OO2

Division

gaskets and seals

Stamped – Extruded – Stamped Industrial Gaskets

Hygienic Tri-Clamp, DIN, SMS Gaskets

FDA – GMP Class VI certified Flange Gaskets

Pre-Moulded Packing and Rings to Size

LIP Seals for Chemical and Food applications

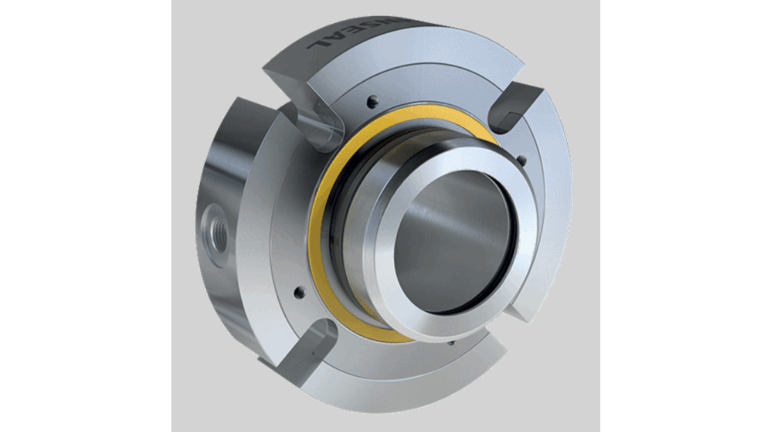

Single and Cartridge Mechanical Seals

EHEDG Hygienic Mechanical Seals for Agitators

2OO6

Maintenance and Service divison

Centrifugal and positive displacement pumps overhaul

Vacuum Units and Compressors Service

Revamping Industrial Gearboxes

Service Industrial Machinery and Exchangers

Industrial Hoses Testing and Certification

Overhaul of Mechanical Seals for Pumps and Agitators

2O11

Division

pumps and valves

Centrifugal and positive displacement pumps

Slurry and slurry pumps

EHEDG food-grade certified pumps

On-Off and Regulating Valves

Valves for slurry and dense products

Food Valves

2O15

Security and Industrial

Protection Division

Absorption – Containment – Storage

Thermal and acoustic protection

Safety covers and flange covers

2O16

Filtration Division

and Textile Manufactures

Industrial Filtration

Joints, Bellows and Compensators

Insulating Coatings

Filters with ePTFE Food grade membrane

Fabrics with Fluortex Multiflon® FDA-GMP Class VI certified

2O22

Hoses and fittings

Division

Suction and delivery hoses for liquids and powders

Special couplings for industrial chemical use

Special couplings for hygienic and food applications

2O24

Division

industrial instrumentation

Flow Meters

Pressure Transmitters

Level Transmitters

Industrial Instrumentation

INDUSTRIAL GASKETS

FOR OVER TWENTY YEARS WE HAVE BEEN OPERATING IN THE FIELD OF STATIC SEALING SYSTEMS FOR PIPING AND INDUSTRIAL EQUIPMENT

Our operating range ranges from paper gaskets to the most sophisticated metal seals for high temperatures and pressures.

With our automatic blade, manual die-cut and semi-automatic cutting centers, we are able to produce standard and custom-made gaskets in extremely short times, guaranteeing a prompt and punctual service for every sealing need.

IN THE INDUSTRIAL SECTOR AND ESPECIALLY IN THE FOOD AND PHARMACEUTICAL SECTORS

Hygienic and sanitary gaskets, Tri-clamps, O-rings in Fep, PTFE and special elastomers, hoses, special connections, FDA food certified pumps and valves, filters with special non-contaminating and microfiltering ePTFE membrane. Our innovative BIOé® line opens up new sealing solutions. A unique material, usable for all processes up to high temperatures (25O°C).

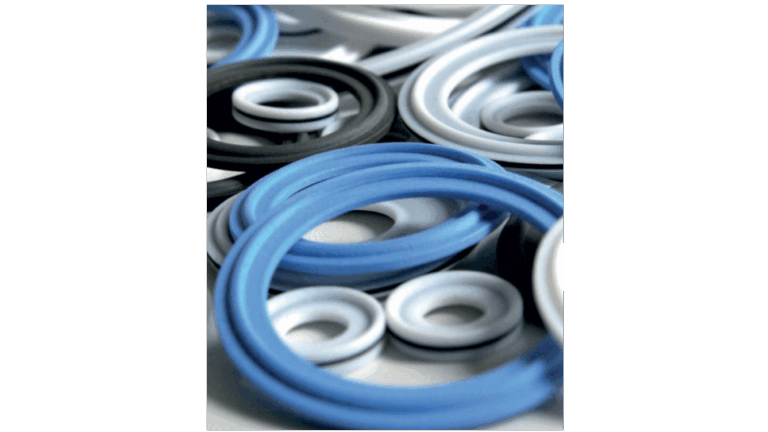

Seals, Lip Seals and Mechanical Seals

THE GROUP IS EQUIPPED WITH AN IMPORTANT WAREHOUSE OF MECHANICAL SEALS, LIP SEAL BEADS AND RINGS

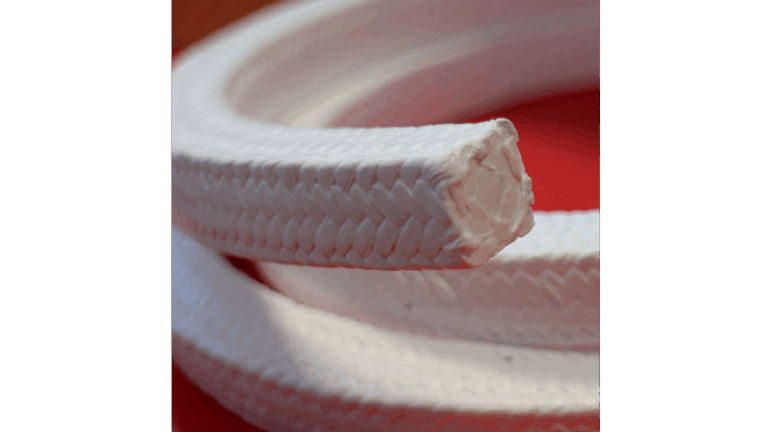

We have component and pre-assembled cartridge mechanical seals for heavy-duty applications on pumps, mixers and reactors. We have a production laboratory for P-SEAL lip seals in single, double version and certified for FDA – GMP hygienic applications. For packing seals, the Group avails itself of German production collaboration to manufacture and market belts, braids for dynamic seals (rotating shafts and pistons) and static seals (tanks, boilers, equipment in general) directly on the Italian territory. In our laboratory we make preformed rings or metre to size and design on request.

HYGIENIC SEALS

WE OFFER A WIDE RANGE OF DYNAMIC SEALS FOR APPLICATIONS ON MACHINES OPERATING IN THE FOOD, COSMETIC AND PHARMACEUTICAL SECTORS:

– FDA-certified braids and packings for static and dynamic use

– EHEDG-certified single and double cartridge mechanical seals

– Single and metal

-cased lip seal rings for machine shaft applications Food & Pharma

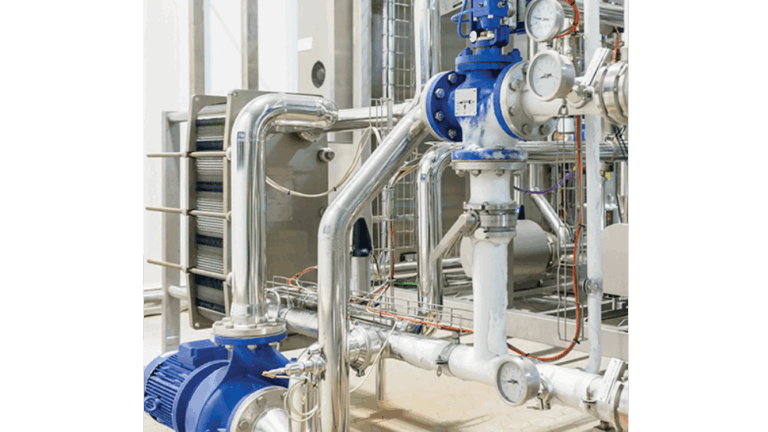

Centrifugal and positive displacement pumps, regulating and on-off valves

IN THE AREA OF FLUID HANDLING AND REGULATION, OUR GROUP HAS ESTABLISHED DISTRIBUTION AND SERVICE RELATIONSHIPS WITH LEADING DOMESTIC AND INTERNATIONAL MANUFACTURERS

We offer sales and maintenance service on centrifugal and positive displacement pumps as well as ball, butterfly, guillotine, sleeve – Pinch Valve and diaphragm or diaphragm valves in standard and safe environment versions.

Hygienic and Food Grade Pumps and Valves

WE DISTRIBUTE VARIOUS HYGIENIC SOLUTIONS FOR HANDLING AND CONTROL

OF FOOD LIQUIDS AND POWDERS:

– EHEDG certified centrifugal pumps

– Volumetric pumps for food and pharmaceutical pastes and creams

– Hygienic valves

– Certified regulation and control systems.

INDUSTRIAL SAFETY AND PROTECTION

ATS GROUP CAN OFFER CONTAINMENT AND STORAGE SYSTEMS, ABSORPTION SYSTEMS FOR INDOOR AND OUTDOOR ENVIRONMENTS IN BOTH GRANULAR AND FABRIC, BARRIER AND CLOTH FORMATS.

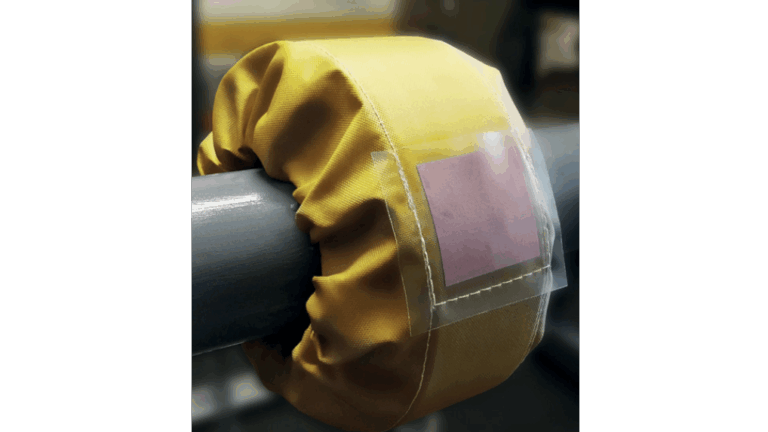

With our in-house textile laboratory, we produce patented protection systems for industrial flanges and couplings. Our SAFETY SHIELD PRO® safety flange covers are designed and patented to ensure maximum performance over long periods, guaranteeing plant and operator safety.

FILTRATION AND TEXTILES

WITH THE CREATION OF THE POLYMER DIVISION, THE ATS GROUP ESTABLISHES ITSELF

AS A QUALIFIED SUPPLIER OF:

– Sleeve filters and industrial filtration systems for powders and liquids

– Textile solutions for the protection and thermal-acoustic insulation

of industrial plants and components

– Maintenance and installation service for filter media and textiles

At our production sites we manufacture all types of filter bags, pocket filters, bags and poly bags as well as cover joints and textile products made to customer specifications. Direct production and packaging allow for extraordinary flexibility and fast delivery.

FILTRATION AND TEXTILES

FILTERS FOR FOOD AND PHARMACEUTICAL POWDERS

THE SPECIAL FLUORTEX MULTIFLON® MEMBRANE APPLIED TO TEXTILE SUBSTRATES ALLOWS US TO MANUFACTURE BAG FILTERS, POLYPROPYLENE AND CUSTOMISED FILTERS FOR INNOVATIVE APPLICATIONS ON PHARMACEUTICAL AND FOOD FILTRATION EQUIPMENT AND PROCESSES.

The ePTFE taping technology allows us to guarantee the non-contamination of filtered products by allowing their 1OO% recovery. Our production includes:

– Bag filters for sugars, flours and food powders

– Multi-sleeve filters for centrifuges and pharmaceutical machines

– Pocket filters

– Special formats

FOR THE INDUSTRIAL SECTOR WE PRODUCE SEVERAL HOSE SOLUTIONS FOR THE DISCHARGE AND LOADING CONCENTRATED CHEMICALS AND SEMI-SOLID PRODUCTS

Our line includes:

– Rubber, composite and PTFE hoses for liquid substances

– Hoses for powders and abrasive substances

– Industrial quick couplings for easy coupling management

– Protection systems in case of hose release or impact

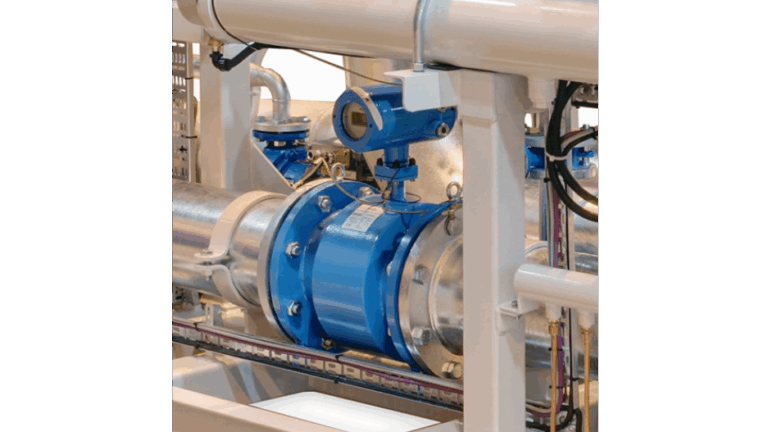

PROCESS INSTRUMENTATION

After having consolidated over the years the cooperation with one of the main flowmeter manufacturing companies, we have established a distribution and service agreement for the entire Italian territory that includes a complete range of measuring instruments for industrial applications.

Now our Business Unit can offer you magnetic flowmeters with electromagnetic sensors with intelligent converter, Vortex flowmeters, fixed and portable inversion ultrasonic flowmeters as well as numerous other solutions for the correct definition of measurements, essential in various industrial production activities. Our technicians are at your disposal for any requests and of course for subsequent service and monitoring of the equipment.

Overhaul of centrifugal and positive displacement pumps

WE CAN CARRY OUT ORDINARY AND EXTRAORDINARY MAINTENANCE ON SINGLE-IMPELLER, MULTI-IMPELLER, SUBMERSIBLE AND SUBMERSIBLE CENTRIFUGAL PUMPS

Positive displacement gear and lobe pumps, peristaltic pumps, progressing cavity pumps, reciprocating piston pumps (dosing and high pressure), pneumatic pumps with single and double diaphragm (dosing and process), magnetic drive pumps, with packing gland or with mechanical seal. We are equipped with our own internal department for cleaning and lapping sealing rings as well as automatic washing machines to manage activities in complete safety.

MAINTENANCE AND SERVICE

OVERHAUL OF VACUUM UNITS

AND COMPRESSORS

WE HAVE HAD IN-HOUSE TECHNICIANS SPECIALIZED FOR OVER TWENTY YEARS IN THE MAINTENANCE AND RECONDITIONING OF SCREW AND RECIPROCATING COMPRESSION UNITS FOR THE PRODUCTION OF TECHNICAL GASES (ACETYLENE, CO2, HYDROGEN, AIR AND NITROGEN PEROXIDE)

Here we guarantee ordinary or extraordinary maintenance assistance with disassembly, cleaning, detail survey, reconstruction and replacement of spare parts to bring the machine to O’clock. For the vacuum sector, we work on liquid ring machines, lobes, pallets of the main brands. Also in this case we can offer services for ordinary maintenance and extraordinary interventions on site.

Revamping of industrial gearboxes

OUR STAFF HAS BEEN WORKING FOR YEARS IN COLLABORATION WITH A LEADING ITALIAN PARTNER IN THE PRODUCTION OF LARGE GEARBOXES AND COMPLETE GEARBOXES

Thanks to this partnership we can guarantee technical control and maintenance interventions on the vast majority of parallel shaft gearboxes, parallel shaft gearboxes with cylindrical gears, planetary gearboxes, bevel gear angles and worm screw angle gearboxes. We can carry out disassembly and survey of the parts in order to prepare the spare parts necessary for a subsequent scheduled maintenance intervention, thus ensuring production continuity.