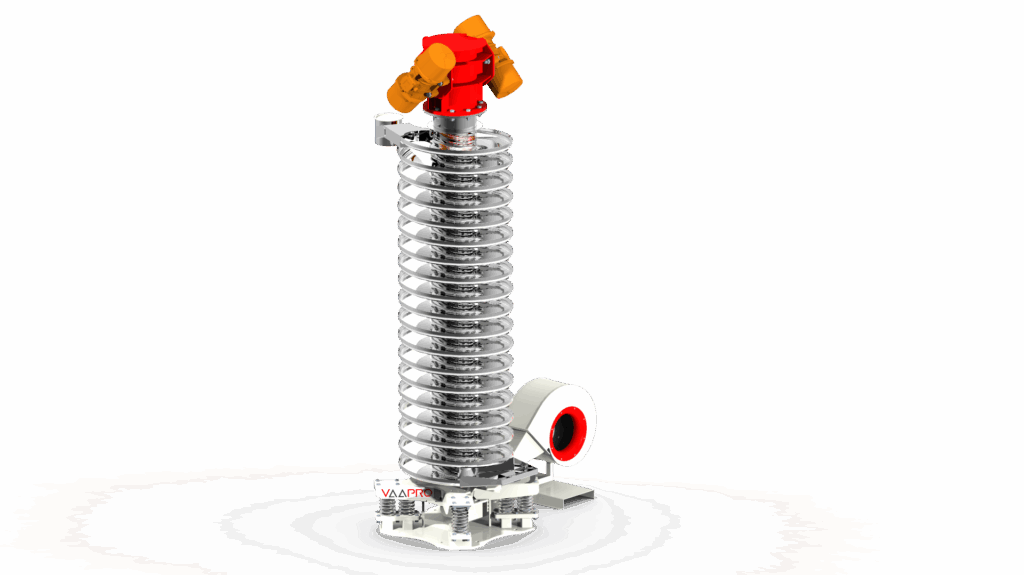

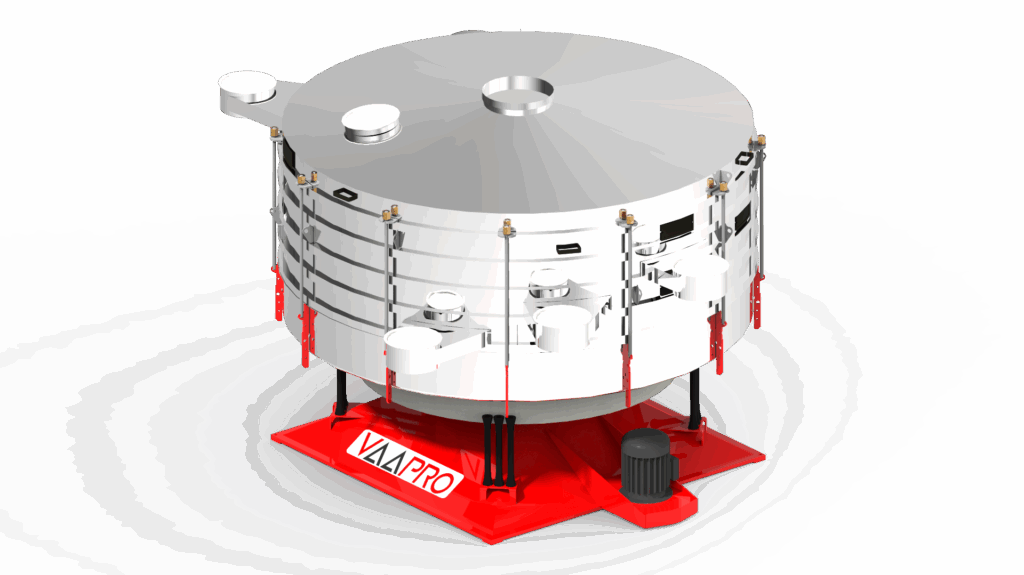

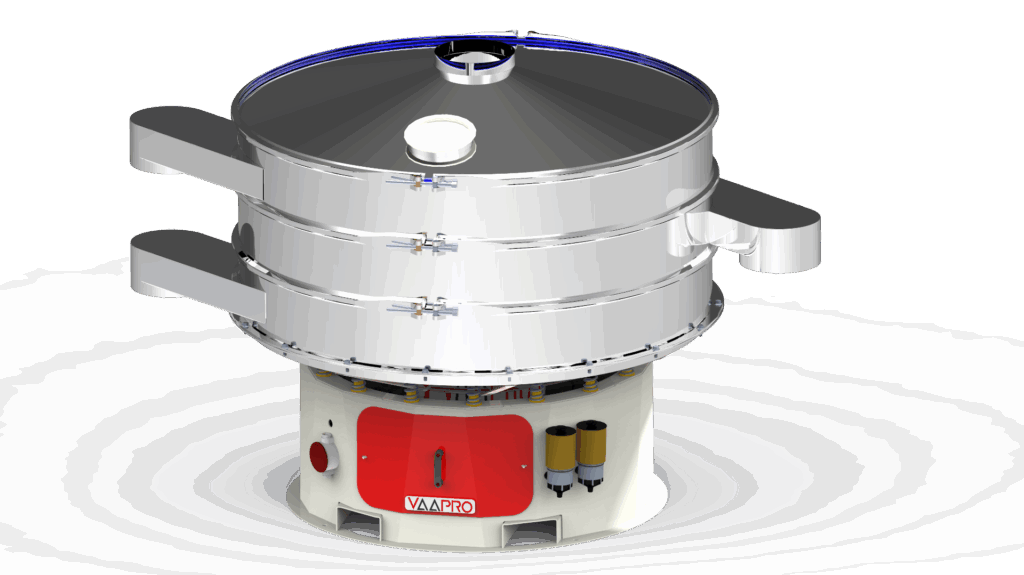

Vaapro Sack Tip Station with Vibrating Sieve – Safe, Clean, and Efficient Material Handling

At Solids Parma 2026, Vaapro presents its Sack Tip Station with Integrated Vibrating Sieve, a compact and ergonomic solution for the safe and controlled introduction of bulk materials into your production line.

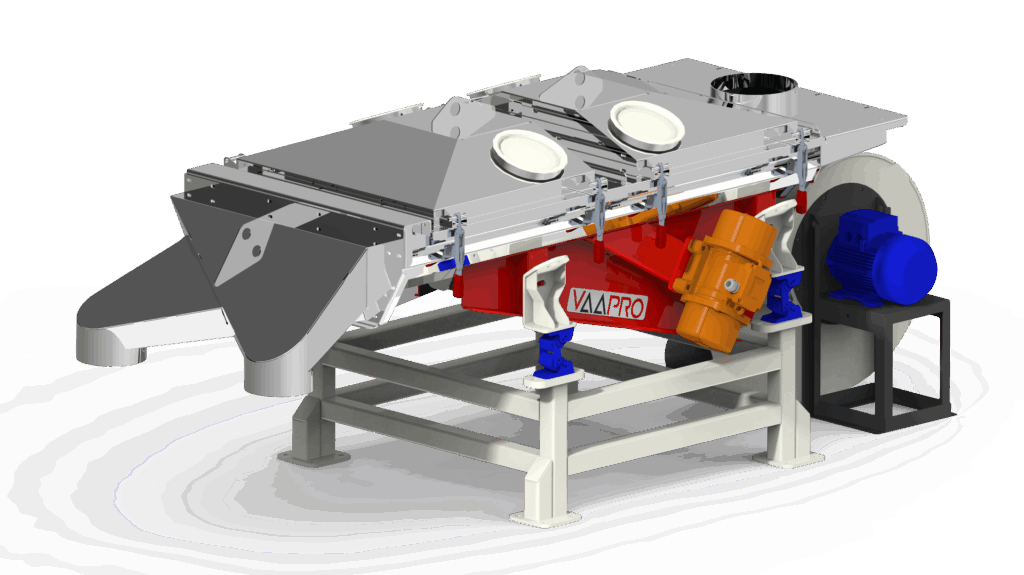

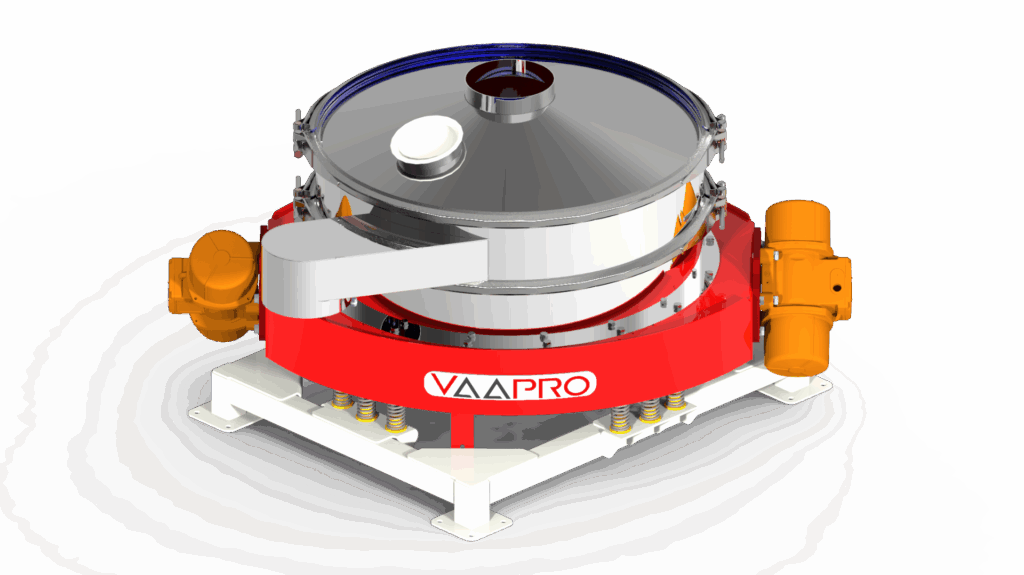

Designed to ensure operator safety, product integrity, and process efficiency, the station allows manual unloading of 15–50 kg sacks, while the integrated vibrating sieve immediately separates lumps, contaminants, and foreign bodies.

Key Benefits:

– Efficient separation of oversized particles and impurities;

– Dust-free operation, with optional integrated extraction system;

– Sturdy stainless-steel construction, hygienic and easy to clean;

– Ergonomic design, featuring a support grid and inspection doors;

– Modular and customizable, suitable for integration into new or existing lines;

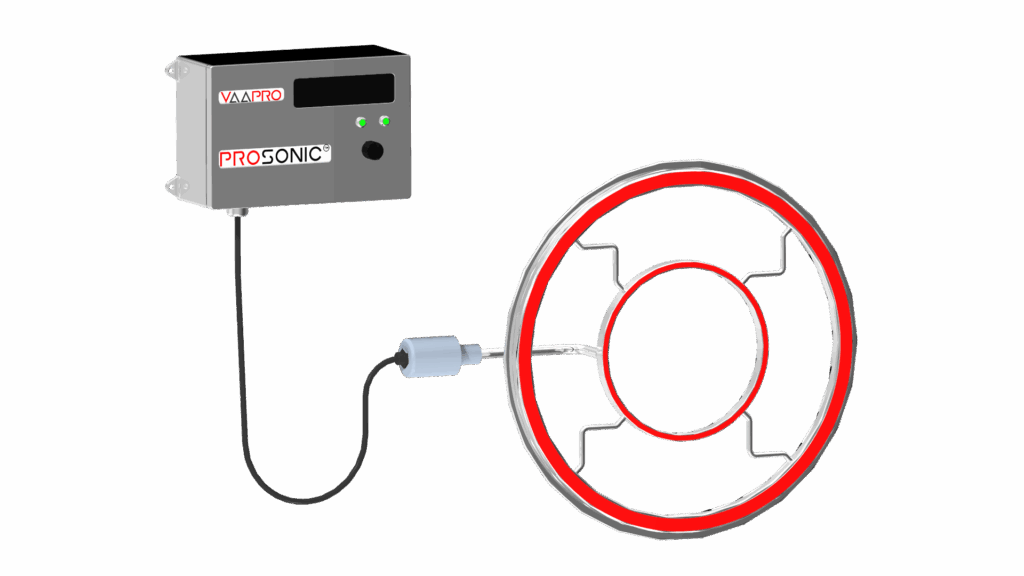

Available with additional features such as ultrasonic mesh cleaning, dust-tight covers, load cells for weighing, and ATEX-certified models for use in explosive atmospheres.

The integrated vibrating sieve ensures a continuous and uniform product flow to downstream equipment, improving quality and minimizing production risks.

Ideal for industries including food, chemicals, pharmaceuticals, plastics, and ceramics, the Vaapro Sack Tip Station helps optimize handling time, improve cleanliness, and boost overall process performance.