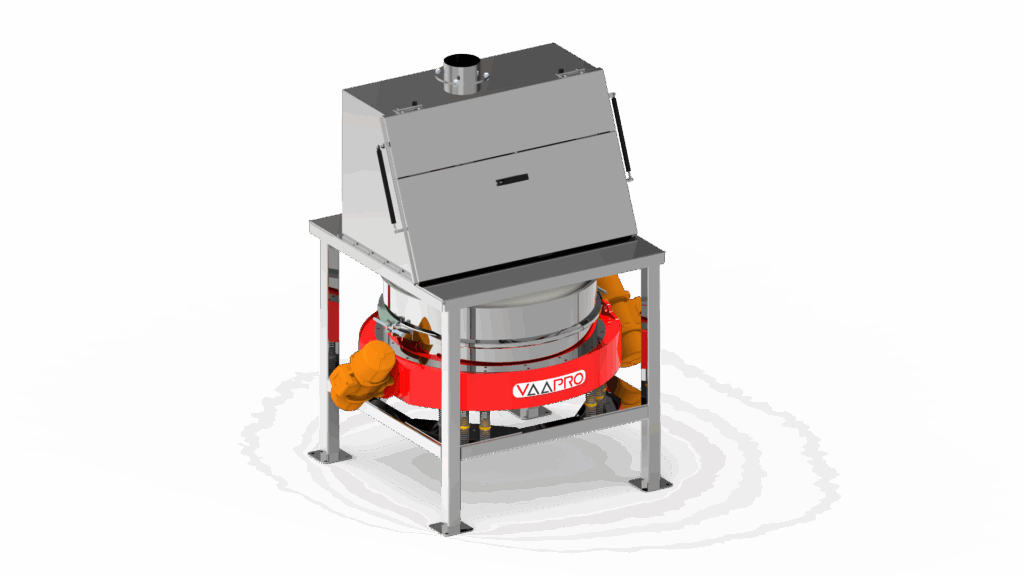

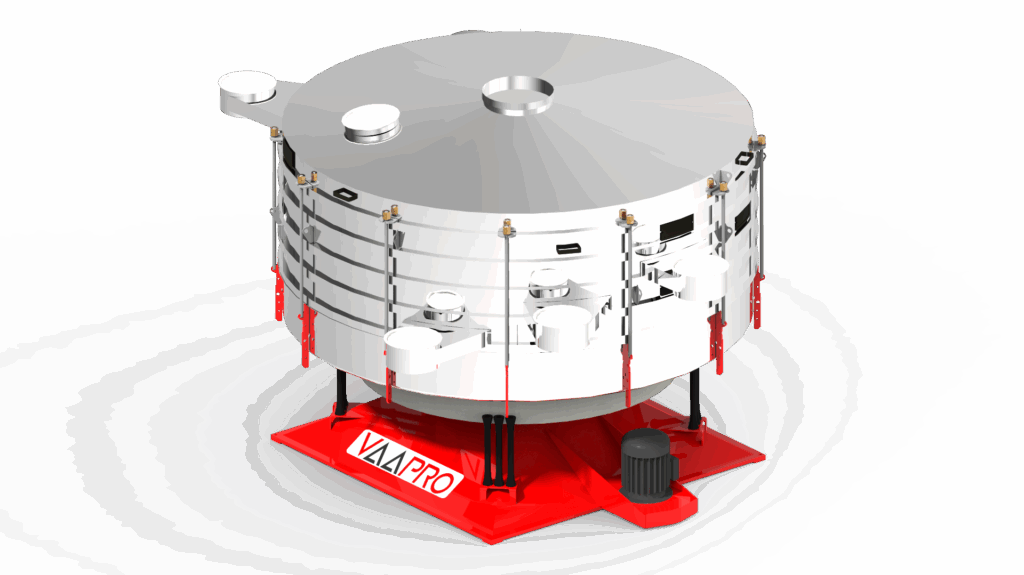

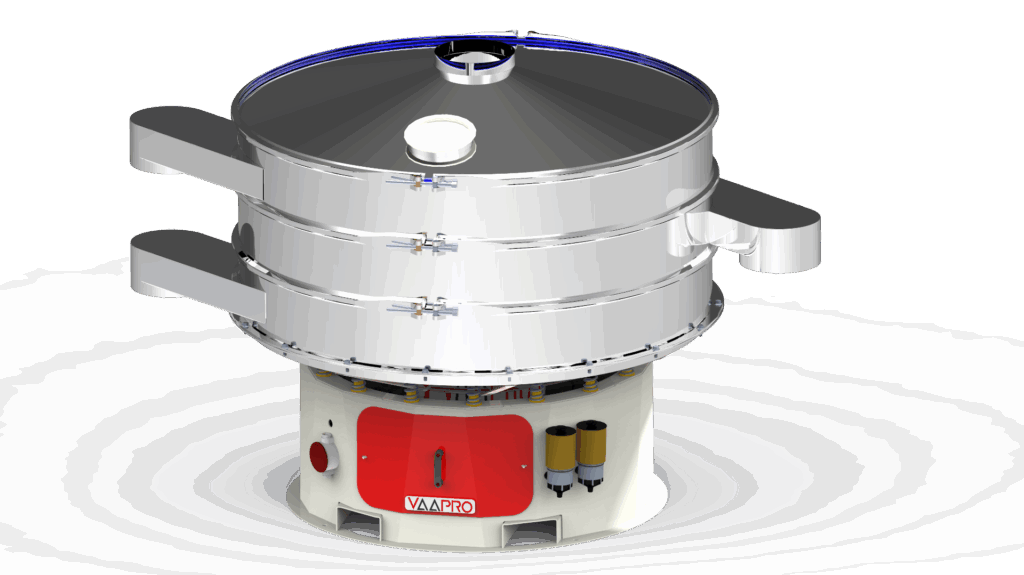

Vaapro Control Vibrating Sieve – Ensuring Quality and Product Safety

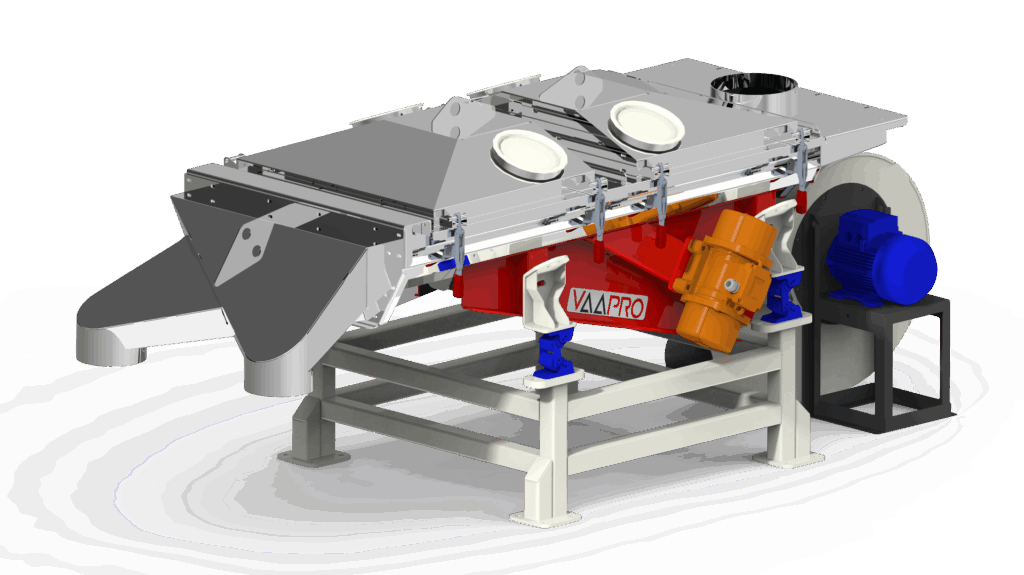

The Vaapro control vibrating sieve is designed for safety screening of powders and granules, efficiently removing foreign bodies, agglomerates, and oversized particles. Installed at the inlet or outlet of production lines, it ensures consistent product quality and protects downstream equipment, helping reduce waste, downtime, and customer complaints.

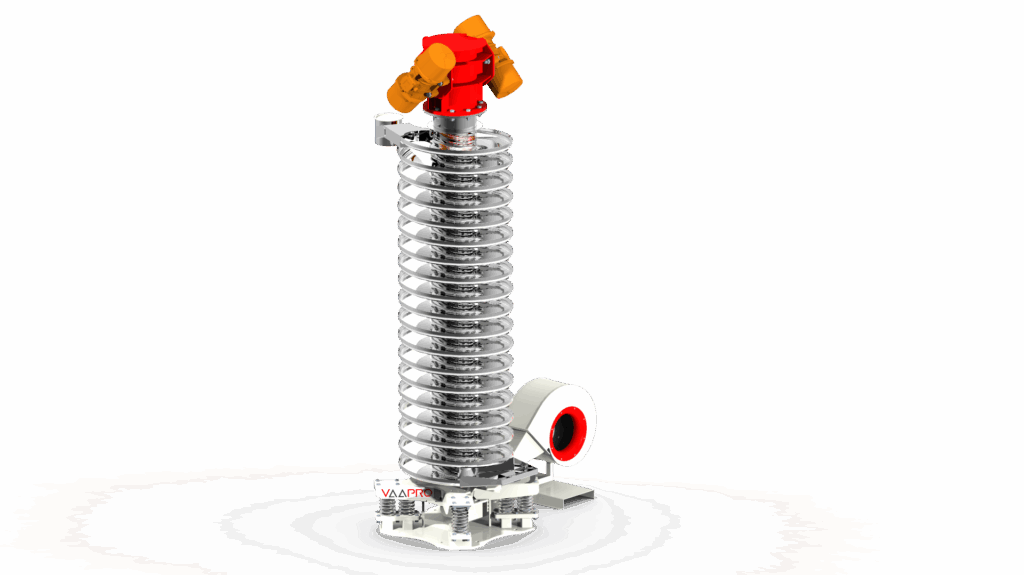

Thanks to its high-frequency circular vibration, it delivers fast and accurate screening even at high throughputs, without compromising precision. Its compact and robust design allows for easy integration into existing systems, such as under silos, hoppers, mixers, or filling machines.

Manufactured in AISI 304 or 316L stainless steel, the control sieve complies with the highest international standards:

– MOCA (EU 1935/2004) for food contact

– FDA compliant for food and pharmaceutical applications

– ATEX certified for use in potentially explosive environments

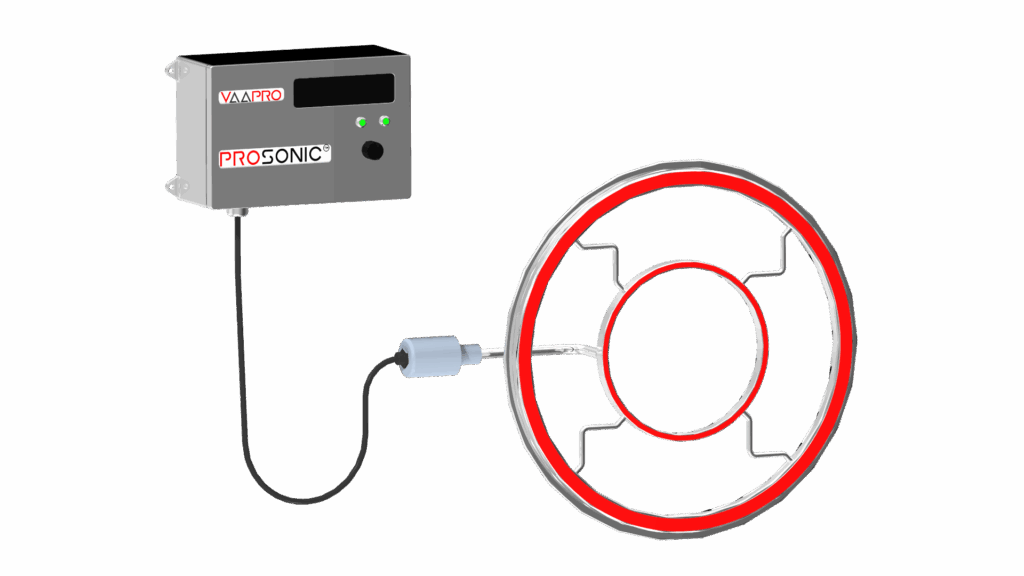

Key features:

– Compact, robust structure for easy integration;

– Quick-release system for fast maintenance and cleaning;

– Interchangeable screens for versatile use;

– Quiet operation and low energy consumption;

– Ideal for inline or batch processes;

Main applications:

Used in quality control processes across industries such as food, chemicals, pharmaceuticals, cosmetics, nutraceuticals, plastics, and ceramics.